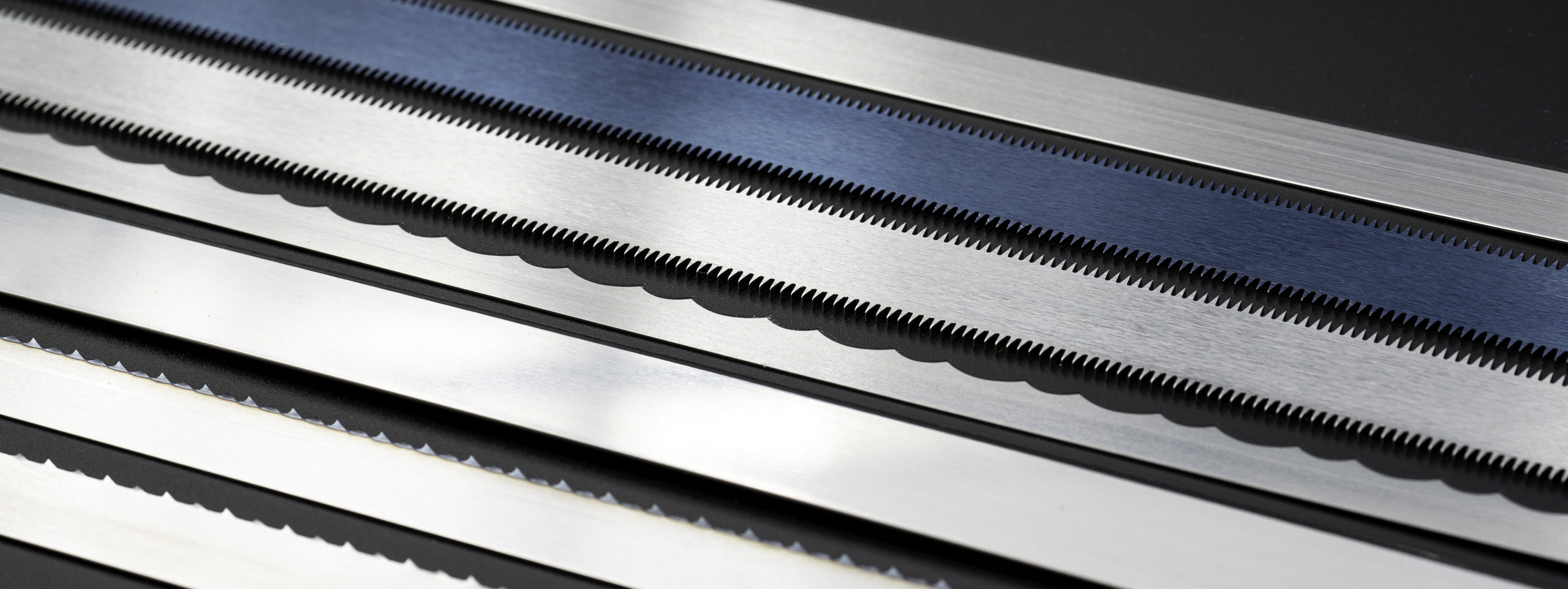

With over 75 years of industry experience, Munkfors has mastered the art of manufacturing band saw blades that meet the rigorous demands of industries where precision and hygiene are essential. Our blades deliver consistent, sharp results, whether cutting fresh meat, frozen fish, or wood for carpentry and sawmills. The meticulous craftsmanship behind each blade guarantees a long lifecycle, reducing downtime and enhancing productivity.

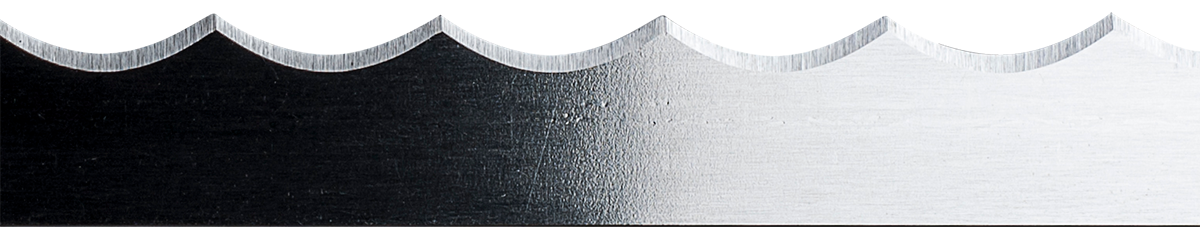

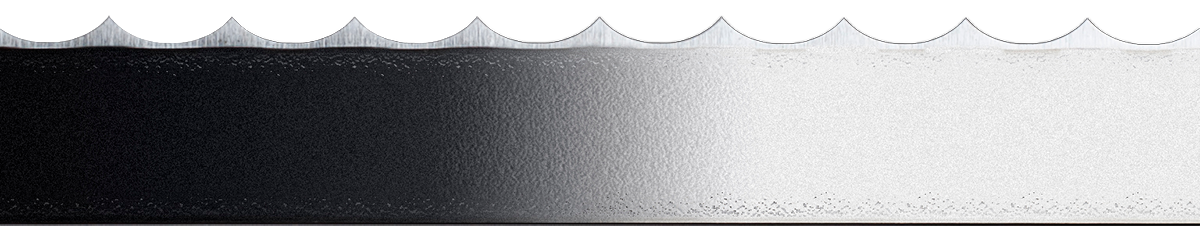

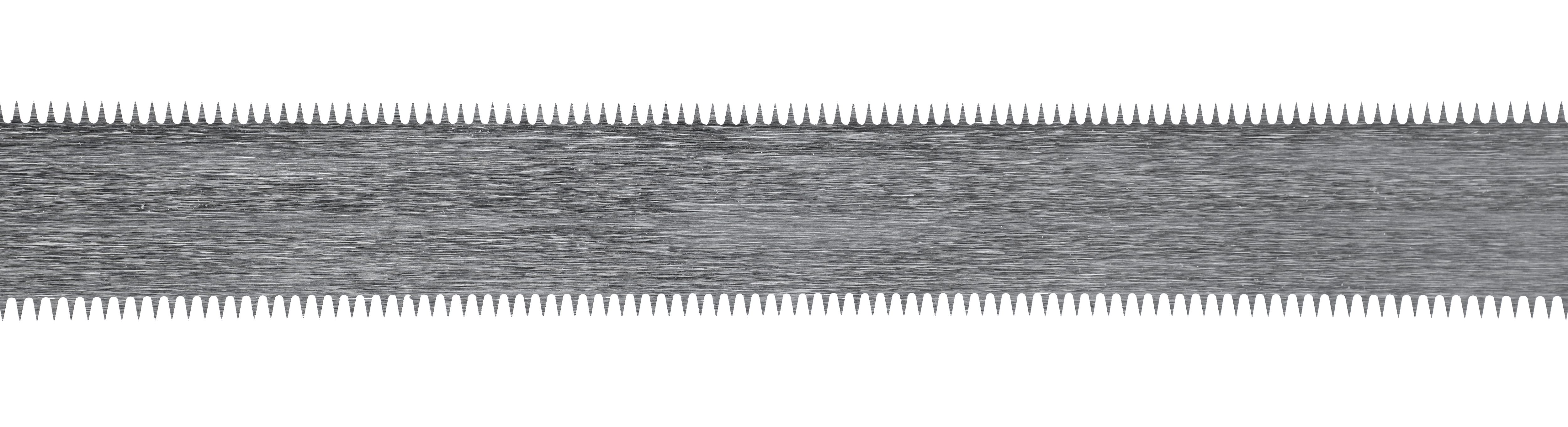

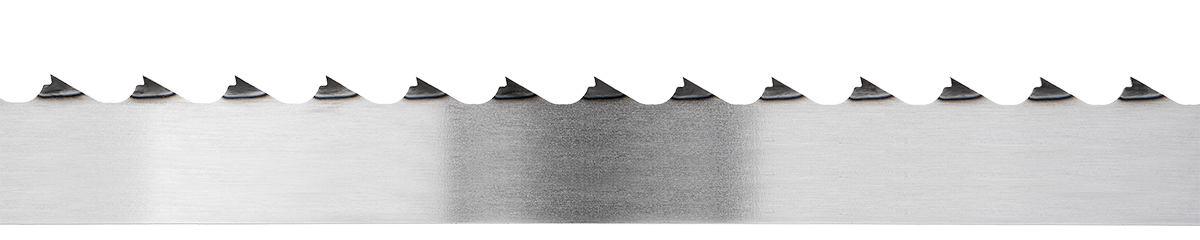

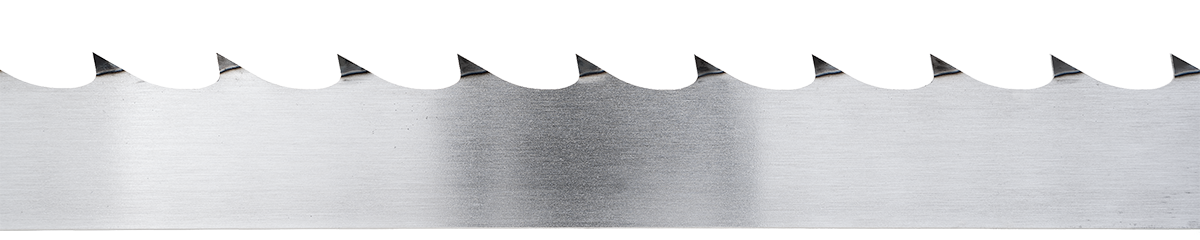

Our extensive range of band saw blades includes specialized options for different materials and applications. For example, our fresh meat band saw blades are engineered to handle the toughest cuts, including thick bones, while our frozen fish blades come in corrosion-resistant materials to withstand harsh environments. Additionally, Munkfors’ innovative profile-grinding technology ensures uniform teeth geometry, providing exceptional cutting accuracy and reliability.

Munkfors is committed to continuous innovation and quality improvement, driven by a passion for excellence that spans three generations of the Hallberg family. Our dedication to producing world-leading products has earned us a reputation for enhancing operational reliability and product quality. By choosing Munkfors band saw blades, you are investing in a tool that optimizes performance, ensuring your operations run smoothly and efficiently.

Whether you are in the food processing industry, woodworking, or any other sector requiring precise cutting solutions, Munkfors offers the perfect blade to meet your needs. Experience the difference that exceptional Swedish craftsmanship can make in your cutting operations with Munkfors band saw blades.

Why Selecting the Right Band Saw Blade Is Crucial

Choosing the correct band saw blade is essential for achieving optimal cutting performance and efficiency. The blade serves as the core of any cutting process, directly influencing the precision, speed, and finish of your work. Whether you process fresh meat, frozen fish, or work with wood in carpentry and sawmills, your choice of blade affects the reliability and quality of your results.

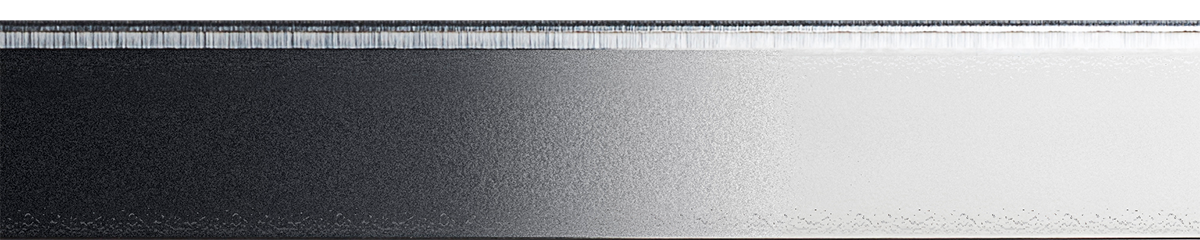

There are specialized blade options for different materials and applications, including corrosion-resistant blades for harsh environments and blades designed for challenging cuts like thick bones. Investing in a superior band saw blade reduces downtime, minimizes waste, and boosts productivity, making it essential for industries where precision and hygiene are critical.

Achieve Consistent Results With Precision Band Saw Blades

Achieving uniform and high-quality cuts starts with selecting a precision-engineered band saw blade. The right blade is pivotal for maintaining consistent cutting results, whether you’re working with fresh meat, frozen fish, or challenging wood materials. Advanced manufacturing processes and superior steel construction deliver exceptional sharpness, durability, and accurate tooth geometry.

This translates into reduced waste, improved product appearance, and less downtime—critical factors for food processors and woodworking professionals aiming for productivity and reliability. Investing in a tailored band saw blade is the key to smooth, efficient, and flawless cutting operations every time.

How the Right Band Saw Blade Boosts Productivity

Selecting the ideal band saw blade from Munkfors is essential for maximizing efficiency and achieving precise results in your cutting operations. Munkfors blade quality directly impacts the speed, accuracy, and finish of every cut, whether you’re processing fresh meat, frozen fish, or working with wood.

High-grade steel and advanced manufacturing techniques from Munkfors ensure that each blade delivers consistent sharpness and durability, reducing downtime and minimizing waste. By choosing a Munkfors blade tailored to your specific material and application, you enhance operational reliability and maintain high standards of hygiene and product quality across your production line.

Questions & Answers

Why is band saw blade quality crucial for cutting performance?

– The quality of a band saw blade directly influences cutting precision, efficiency, and the finish of the product. Using high-quality blades made from durable materials ensures sharper cuts, reduces downtime, and boosts productivity. This is essential in industries where accuracy and reliability are priorities.

Which materials are suitable for high-performance band saw blades?

– High-performance band saw blades can cut a wide range of materials, such as fresh meat, frozen fish, wood, vegetables, bread, and products with thick bones. Specific blade options are available to deliver optimal results for each material and application.

How do advanced manufacturing methods enhance band saw blade durability?

– Advanced manufacturing, like profile-grinding technology, produces uniform tooth geometry and uses high-grade steel. This combination leads to blades with superior sharpness, longer life spans, and less maintenance, which increases both reliability and productivity in operations.

What advantages does Swedish steel offer for band saw blades?

– Swedish steel is famous for its strength and precision. Munkfors blades made from Swedish steel provide exceptional durability, consistent sharpness, and reliable performance. This ensures clean cuts and reduces waste in demanding industrial settings.