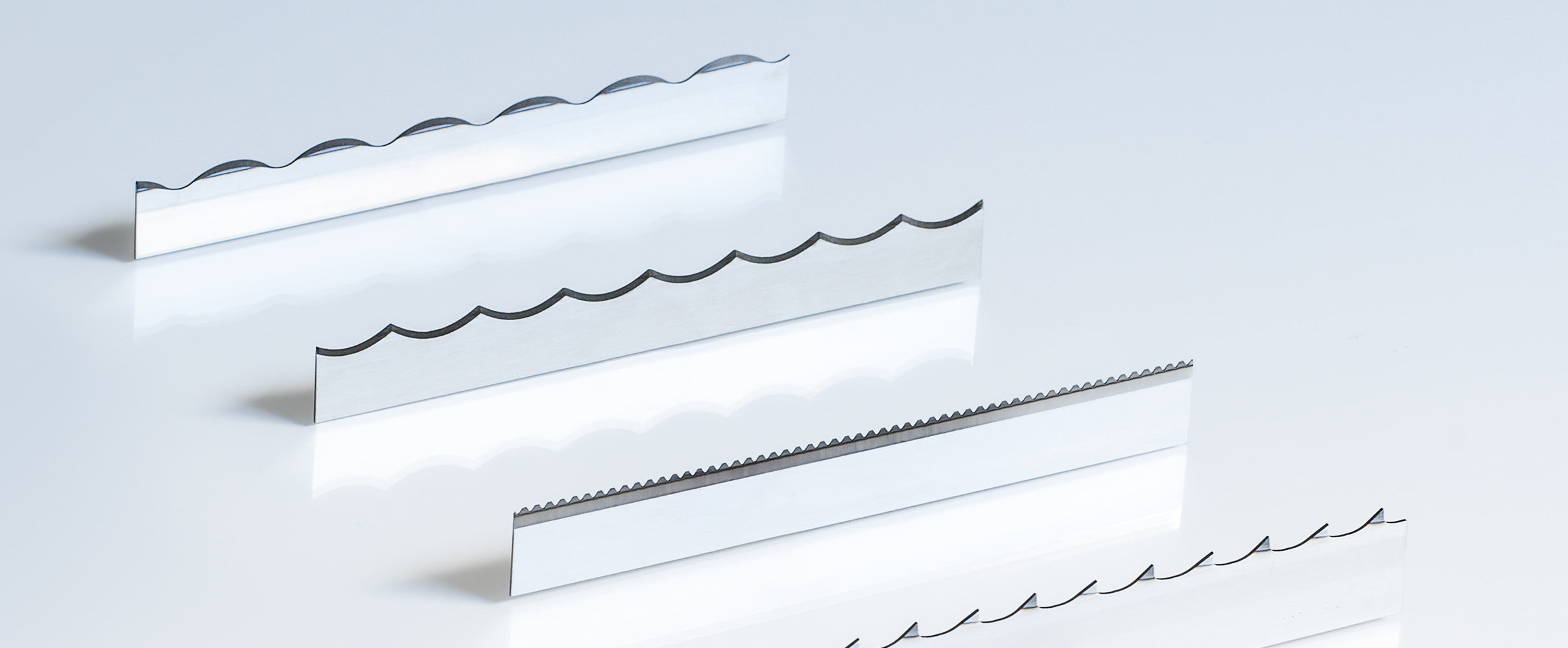

To get the most efficient results requires the proper band saw blade – select the right tool for the right job. If you go for the Munkfors brand your blades will have the perfect cutting and slicing abilities. Our optimized material treatment ensures a longer blade lifetime, which will lead to minimum downtime, less maintenance, a maximized yield and a clean and uniform final result.