In the food industry, Munkfors bandsaw blades deliver unmatched sharpness and functionality, ensuring clean and precise cuts on various products, including meats, poultry, and other kinds of meat. This precision not only enhances the appearance of the final product but also boosts workplace safety by reducing the risk of accidents during cutting operations.

For the woodworking sector, Munkfors provides a wide range of bandsaw blades tailored to different challenges, from pallet manufacturing to carpentry. Engineered to handle the toughest materials, these blades allow for faster cutting speeds and extended blade life. This ensures that clients achieve optimal life cycle economy while maintaining top-notch productivity and performance.

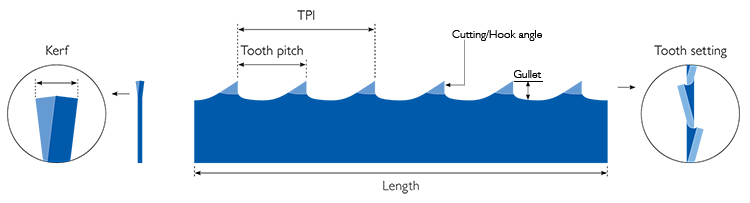

Committed to innovation and continuous improvement, Munkfors designs its bandsaw blades with identical tooth sequences and uniform cutting geometry, crucial for consistent surface finishes and maximizing operational efficiency. The use of Swedish steel not only boosts the toughness and sharpness of the blades but also supports sustainable manufacturing practices.

Dedicated to craftsmanship and quality, Munkfors ensures every blade reflects its commitment to excellence. These products are critical components in environments where high output and hygiene are essential, making them indispensable to clients’ operations. With a legacy of innovation and a focus on customer satisfaction, Munkfors continues to set the standard for bandsaw blade performance worldwide.

Advanced Bandsaw Technology for Superior Cutting

Unlock the full potential of your operations with advanced bandsaw blades from Munkfors, engineered for both food processing and woodworking environments. Utilizing high-grade Swedish steel, Munkfors bandsaw options deliver outstanding sharpness, resilience, and consistent cutting accuracy.

In the food sector, precision-crafted blades from Munkfors allow for smooth, safe cuts on a variety of products such as meat, fish, poultry, and cheese, promoting cleaner results and supporting hygiene standards. For woodworking applications, the Munkfors range includes blades optimized for tasks like pallet manufacturing, carpentry, and sawmills, able to withstand challenging materials while maintaining fast cutting speeds and extended blade life.

With meticulous attention to tooth geometry and uniformity, Munkfors bandsaw blades ensure dependable surface finishes and efficient performance, helping customers achieve productivity, reliability, and cost efficiency in even the most demanding settings.

Unlocking Efficiency with Advanced Bandsaw Solutions

Experience how advanced bandsaw technology can improve your operations. Modern bandsaw blades, made from premium Swedish steel, are engineered for food processing and woodworking applications, offering exceptional sharpness and durability. These blades fulfill the diverse needs of demanding environments, ensuring smooth, precise cuts and minimal waste.

Consistent tooth geometry and robust construction result in longer blade life and reduced downtime, supporting continuous productivity. Whether cutting tough hardwoods or processing meat and cheese, selecting the right bandsaw improves output quality, operational safety, and efficiency.

Benefits of High-Quality Bandsaw Blades

Selecting the right bandsaw blade is essential for achieving precise, clean cuts and maximizing productivity in both food processing and woodworking industries. High-quality bandsaw blades from Munkfors, crafted from premium Swedish steel, offer superior sharpness, durability, and consistent performance.

These blades are engineered to handle demanding materials, ensuring smooth operation and extended blade life. Investing in advanced bandsaw technology from Munkfors allows businesses to benefit from improved safety, reduced downtime, and optimal surface finishes, making these blades a critical component for reliable and efficient production environments.

Questions & Answers

What makes Munkfors bandsaw blades ideal for food processing applications?

– Munkfors bandsaw blades are designed for exceptional sharpness and precision, delivering clean and accurate cuts on meats, poultry, fish, and cheese. Their construction supports workplace safety and hygiene, making them a preferred choice in the food processing industry for reliable, high-quality results.

How do Munkfors bandsaw blades support woodworking professionals?

– Munkfors bandsaw blades are engineered to cut through tough materials in woodworking, including hardwoods and pallets. Their sharpness and durability enable faster cutting speeds, longer blade life, and consistent surface finishes. This helps woodworkers maintain high productivity and achieve optimal life cycle economy.

What is the significance of Swedish steel in Munkfors bandsaw blades?

– Swedish steel is renowned for its high quality, toughness, and sharpness. Munkfors incorporates premium Swedish steel in their bandsaw blades to provide maximum durability, precise cutting performance, and long-lasting reliability, supporting both sustainable manufacturing and operational efficiency.

Which features define high-performance bandsaw blades from Munkfors?

– High-performance bandsaw blades from Munkfors are characterized by uniform tooth geometry, consistent tooth sequences, and advanced design for reliable cutting. These blades deliver outstanding sharpness, durability, and resilience, making them essential for industries that demand accurate, efficient, and hygienic operations.