Selecting a Munkfors rasper blade is the first step to increasing both the productivity and profitability of your starch extraction business.

Superior rasper blades from Munkfors

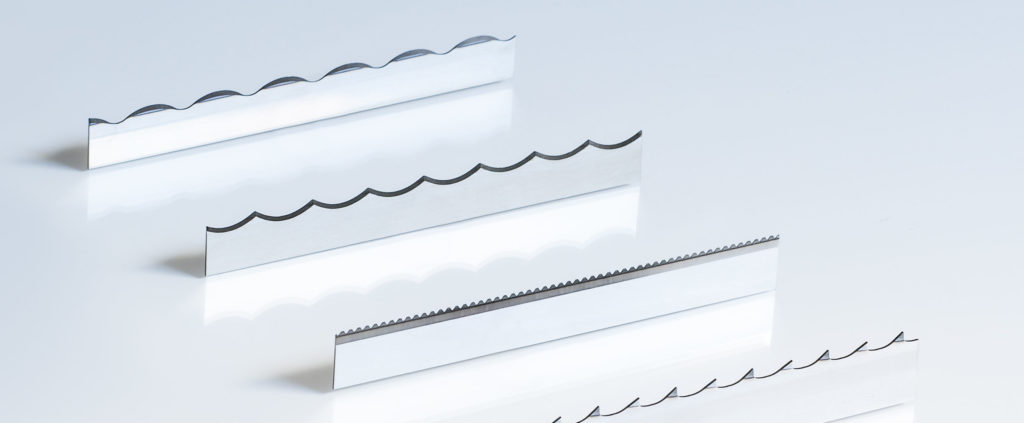

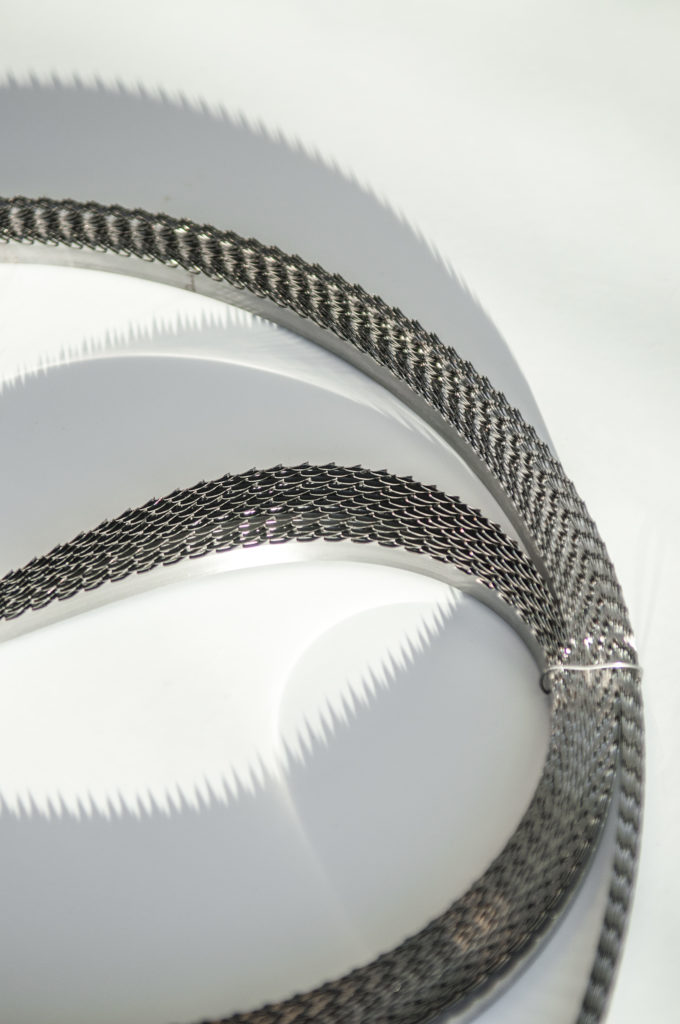

The efficiency of the raspering process primarily determines the yield of starch extracted from tapioca/potatoes. In addition to the right raspering machine, the quality of the blades as regards their material, strength, teeth profile and lifetime plays an important role in maximizing starch yields. This is why selecting a Munkfors high-performance blade is the first step to increasing both the productivity and profitability of your starch extraction business. By choosing a blade from Munkfors you will get a blade with an exceptionally long life cycle – even under tough conditions.

Unique grinding technology

Munkfors rasper blades are manufactured using our unique and patented profile-grinding technology that results in a number of major benefits:

- Sharper blades

- Longer blade lifetime

- Maximal product yields

- Minimum downtime

High-grade materials and our advanced grinding method result in rasper blades with teeth with the ideal profile. This enables sharper cutting than ordinary competitive blades, and smoother operation and less production wear and tear.